Foam Signs

|

|

- Core of structure is molded expanded polystyrene, 1#C.F.

- Aromatic fast cure urethane, impact resistant, hard coat finish

- Finished surface is 100% aggregated acrylic

- 3″ or 4″ Schedule 40 PVC pipe is bonded into center

of structure. - Steel pipe is inserted into structure on site during installation and secured with expanding polymeric resin foam

- Concrete footing as required by local code, post must typically extend 2?-4? into concrete

THE FOAMCRAFT DIFFERENCE:

- DURABILITY– Hardcoat second to none- Highly impact, insect, and weather resistant. Ask for our durability sample, the “Hammer Sample”- a piece of foam trim sprayed with our plastic hardcoat.

- VERSATILITY– We build Custom designs, our Standard Model Designs, and Modified Standard Model Designs built to Any Dimension. Incorporate Iluminated Cabinets, all types of Sign and Tenant Panels, Stud-Mounted Letters, or let us Raise or Recess your graphics for you. Your choice of colors.

- COST EFFECTIVE – Affordable Pricing

- EASY TO INSTALL – Two Simple Ground Mount Systems, Signs relatively lightweight.

- EASY TO SELL – We help you sell- Free marketing material (CD, Standard Model Drawings, Color Charts, and Brochures) and support, unmatched customer service.

- CUSTOMER SERVICE – Quick quotes, Experienced Staff- Do not hesitate to give us a call.

- DELIVERY – 3 manufacturing facilities for convenient low cost shipping rates. Tyrone, GA – Allentown, PA – Clifton, NJ

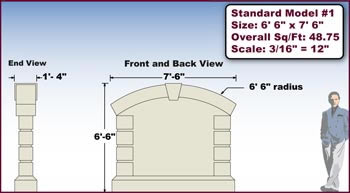

Shape 1

PDF DOWNLOAD

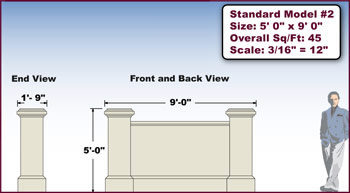

Shape 2

PDF DOWNLOAD

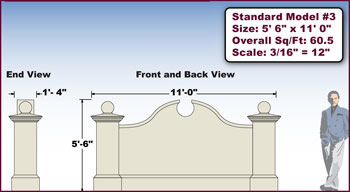

Shape 3

PDF DOWNLOAD

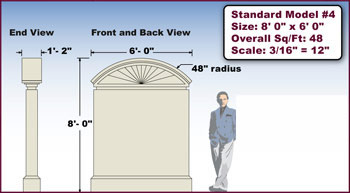

Shape 4

PDF DOWNLOAD

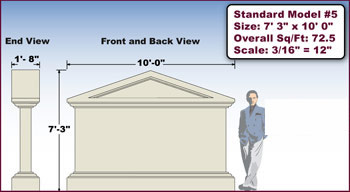

Shape 5

PDF DOWNLOAD

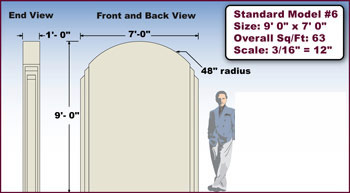

Shape 6

PDF DOWNLOAD

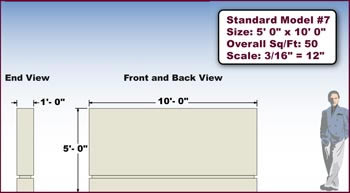

Shape 7

PDF DOWNLOAD

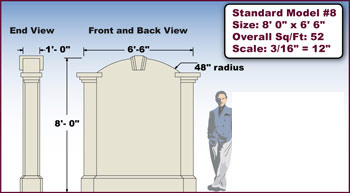

Shape 8

PDF DOWNLOAD

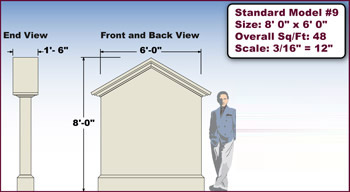

Shape 9

PDF DOWNLOAD

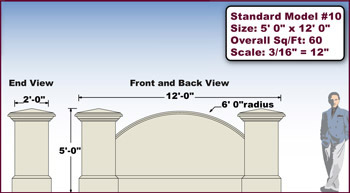

Shape 10

PDF DOWNLOAD

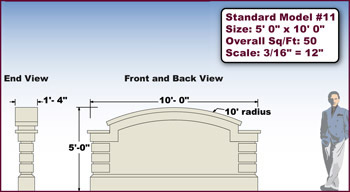

Shape 11

PDF DOWNLOAD

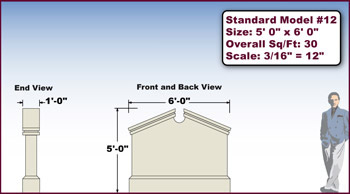

Shape 12

PDF DOWNLOAD

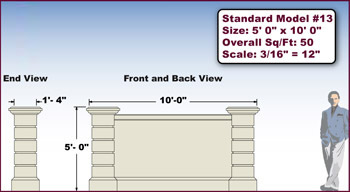

Shape 13

PDF DOWNLOAD

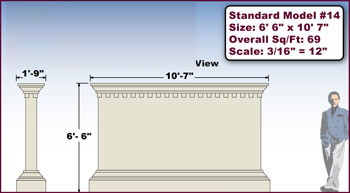

Shape 14

PDF DOWNLOAD

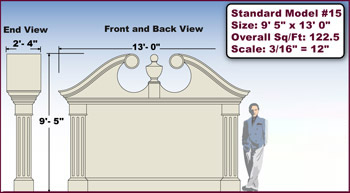

Shape 15

PDF DOWNLOAD

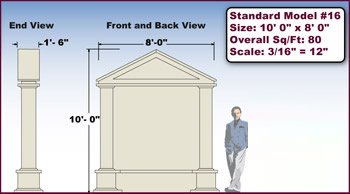

Shape 16

PDF DOWNLOAD

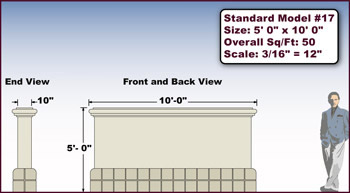

Shape 17

PDF DOWNLOAD

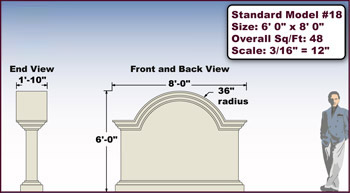

Shape 18

PDF DOWNLOAD

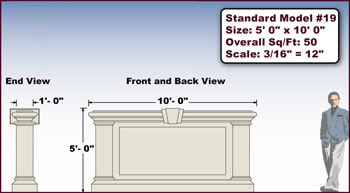

Shape 19

PDF DOWNLOAD

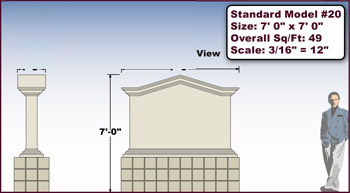

Shape 20

PDF DOWNLOAD

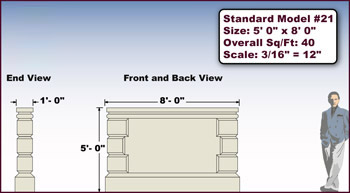

Shape 21

PDF DOWNLOAD

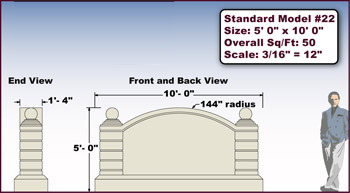

Shape 22

PDF DOWNLOAD

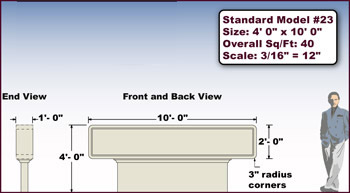

Shape 23

PDF DOWNLOAD

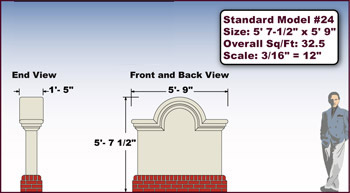

Shape 24

PDF DOWNLOAD

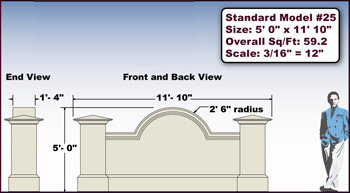

Shape 25

PDF DOWNLOAD

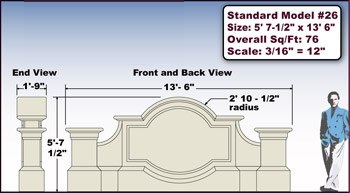

Shape 26

PDF DOWNLOAD

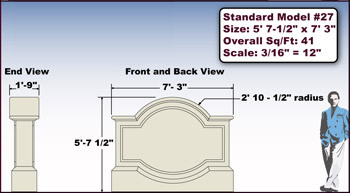

Shape 27

PDF DOWNLOAD

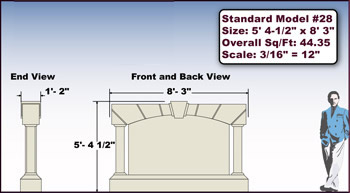

Shape 28

PDF DOWNLOAD

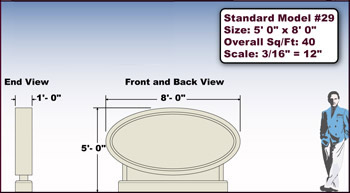

Shape 29

PDF DOWNLOAD

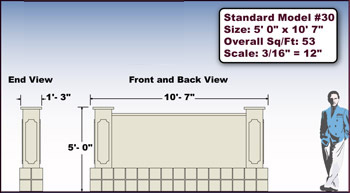

Shape 30

PDF DOWNLOAD

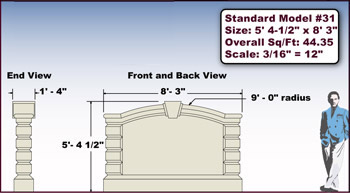

Shape 31

PDF DOWNLOAD

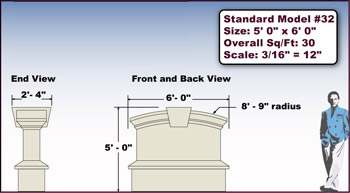

Shape 32

PDF DOWNLOAD

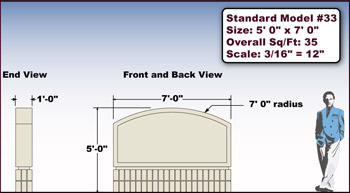

Shape 33

PDF DOWNLOAD

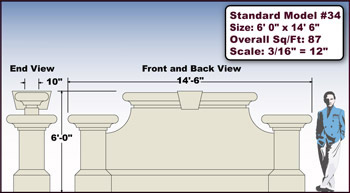

Shape 34

PDF DOWNLOAD

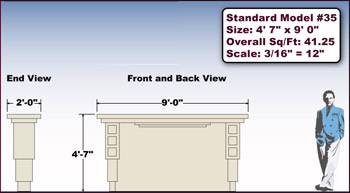

Shape 35

PDF DOWNLOAD

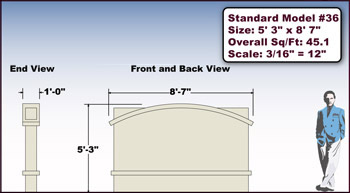

Shape 36

PDF DOWNLOAD

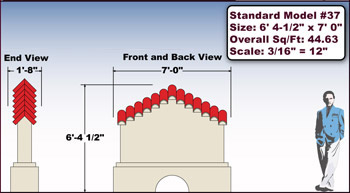

Shape 37

PDF DOWNLOAD

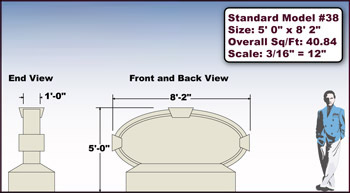

Shape 38

PDF DOWNLOAD

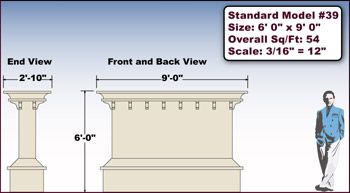

Shape 39

PDF DOWNLOAD

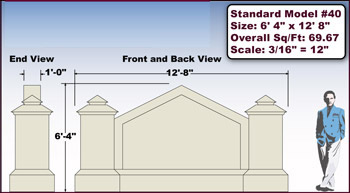

Shape 40

PDF DOWNLOAD

Key Features:

- Easy Installation – prefabricated, no site mess or weather delays.

- Better looking – no exposed seams or fasteners, no “oil canning” as

is likely with aluminum or plastic signs. Durable – Time proven fade

resistant finish, weather and insect proof. - Easily repaired if unlikely damage occurs.

- Easily transported due to low weight and removable mounting posts.

- Standard models available for simple design & layout.

- Custom models available and welcome.

We also fabricate custom caps, columns, bases, pole covers & architectural

trim.

Mounting:

- Mounting is to be “Direct Burial” method of installation. PVC

post sleeves are embedded into the sign core to allow steel mounting

posts to slide in place just prior to mounting. Note: Steel posts are

not included.

Installation:

- Step#1: Determine placement of sign and location of mounting holes.

- Step#2: Utilize post hole diggers or auger drill, dig two holes, depth

as required. - Step#3: Place steel posts into sleeves into bottom of sign, spray expanding

polymeric resin foam into gap around post. - Step#4: Place a couple of

cinder blocks or any other “spacer device” on ground beside

holes. - Step#5: Place sign onto blocks, placing post in the holes.

- Step#6: Mix concrete according to directions on bag and pour into holes.

- Step#7: Remove spacer blocks and allow sign to rest on ground.

- Step#8: Level sign, clean up any debris, you’re finished!